What Can Marking Machines Do?

September 6, 2023 6:01 pm Leave your thoughts

1. Permanent Marking:

The primary function of marking machines is to create permanent markings on different materials. Whether it is metal, plastic, glass, or even organic materials, laser marking provides a durable and long-lasting mark. This is particularly useful in industries such as automotive, aerospace, and electronics, where traceability, branding, and identification are essential.

2. Identification and Barcoding:

Marking machines can create high-quality barcodes, serial numbers, and other identification codes on various surfaces. These codes enable easy tracking, inventory management, and product authentication. Laser marking allows for small, precise markings, ensuring that codes are clear and readable, even on tiny components.

3. Customization and Personalization:

In industries like jewelry, promotional products, and consumer goods, customization and personalization play a crucial role. Marking machines can easily engrave logos, names, or any other desired design on items, enhancing their uniqueness and value. This capability allows businesses to offer personalized products, creating a strong connection with their customers.

4. Anti-Counterfeiting Measures:

Counterfeiting is a widespread issue affecting industries globally. Marking machines provide an effective tool to incorporate anti-counterfeiting measures in products. By engraving unique codes, holograms, or specialized patterns, manufacturers can enhance product security and protect their brand reputation.

5. Surface Texturing:

Marking machines can also perform surface texturing to enhance the aesthetic appeal or functional properties of an object. By adjusting the laser settings, textures like patterns, logos, or even tactile grips can be created on materials such as metal or plastics. This opens up creative possibilities for designers and allows for product differentiation.

6. Cutting and Etching:

Beyond marking, laser machines can also cut thin materials with high precision. This capability is valuable in industries like electronics, where delicate components or circuit boards need to be precisely cut. Additionally, marking machines can etch or remove material from a surface, creating indented or raised designs on various materials.

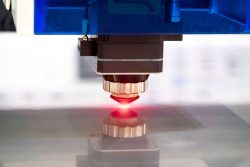

7. High-Speed and Non-Contact Process:

Marking machines offer a non-contact method of marking, meaning there is no physical pressure or tooling involved. They use a focused beam of light to perform the marking, resulting in a clean and precise finish. The process is also fast, making it ideal for high-production environments where efficiency is critical.

8. Environmental Benefits:

Compared to traditional marking methods like inkjet or chemical etching, laser marking machines offer several environmental benefits. They do not require the use of chemicals or solvents, minimizing waste and reducing the overall ecological footprint. Additionally, laser marking is a low-energy process, further contributing to its sustainability.

Conclusion:

Marking machines, utilizing laser technology, have revolutionized the way surfaces are permanently marked across industries. From creating identification codes and barcodes to customization and anti-counterfeiting measures, the capabilities of marking machines are vast. The ability to perform surface texturing, cutting, and etching adds to their versatility. With their high-speed, non-contact process and environmental benefits, marking machines have become an indispensable tool for businesses seeking efficient, precise, and sustainable marking solutions.

Got Questions? Let Us Help!

Categorised in: Laser Engraving

This post was written by admin