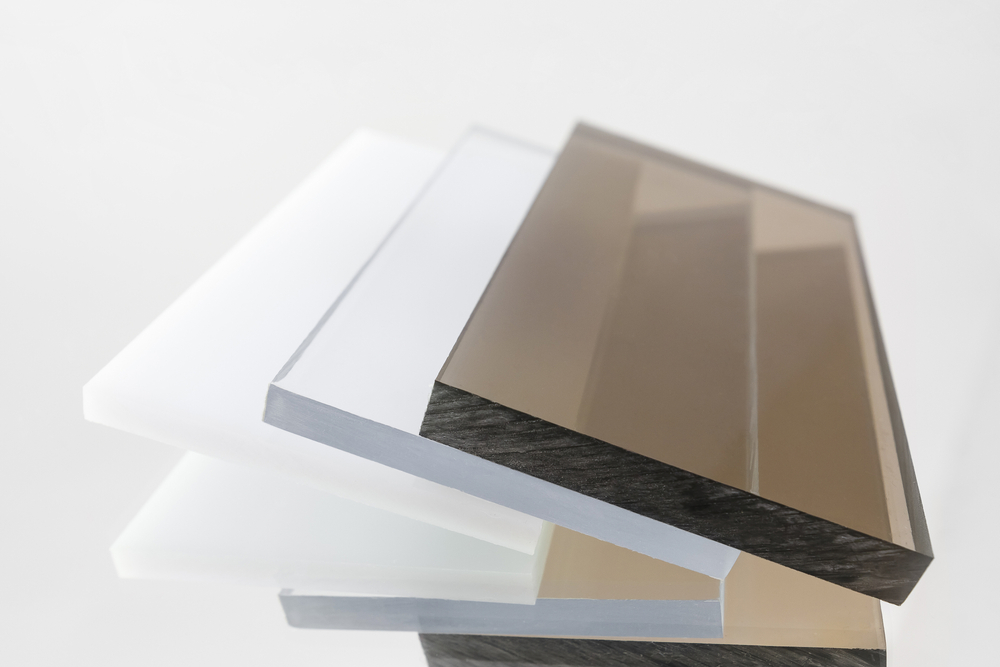

Custom plastic fabrication plays a crucial role in many industries, providing tailored solutions for businesses that need precision, durability, and adaptability in their components. In Orem, UT, the demand for reliable and high-quality plastic fabrication services is growing steadily. With a thriving business landscape that spans technology, manufacturing, retail, and construction, companies in Orem are

READ MOREAuthor: admin

Why Businesses in Orem, UT Choose Local Plastic Fabrication Over National Suppliers

In Orem, UT, a growing number of businesses are choosing local plastic fabrication companies over national suppliers. This shift isn’t merely a trend; it reflects a deeper understanding of what truly matters to companies seeking reliable and tailored solutions for their plastic needs. Whether it’s for industrial parts, retail displays, or custom enclosures, the decision

READ MORESwitching from Prototype to Production: When to Use D & D Plastics for Your Injection Molding Needs

Turning a great idea into a real, functional product involves more than just vision. At D & D Plastics, we help bring that concept to life with expert guidance and hands-on fabrication. As a design and development company with over 35 years of experience, we specialize in both prototype fabrication and full production services, allowing

READ MOREWhy Vacuum Forming and CNC Machining Are Smart Plastic Fabrication Choices for Custom Projects

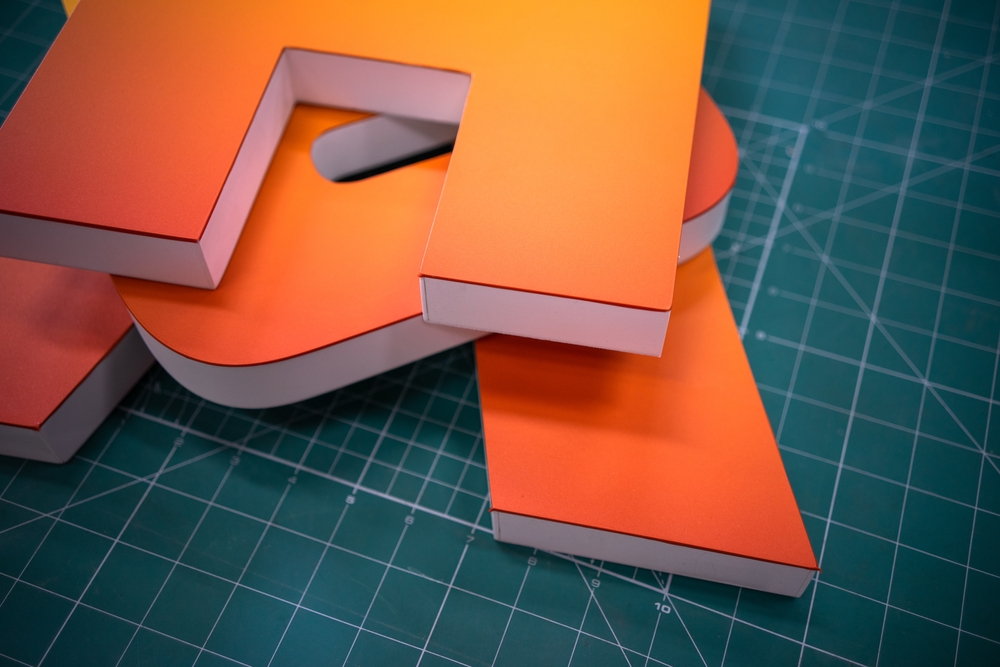

Plastic fabrication has evolved rapidly to meet the demands of today’s fast-paced and design-driven world. Whether for industrial prototypes, custom components, or unique product enclosures, the need for adaptable and precise plastic fabrication methods has never been greater. In Utah, two methods have emerged as top contenders for creating high-quality, custom plastic parts: vacuum forming

READ MOREThe Major Advantages of Using Plastic Injection Molding for Your Product

Plastic injection molding is just one plastic fabrication method that can take your ideas from concept to reality. To form a plastic part, resin or other plastic materials are fed into a hopper where they’re heated until liquefication. Then the plastic is injected into a metal mold, where it cools and is ejected for quality

READ MORE